The series “Iron Chef” features a battle in the kitchen, between a professional and well respected chef, and one of the Food Network’s Iron Chefs.

The two chefs battle it out for an hour in their side-by-side kitchens, and then present their dishes to a panel of judges, who get to decide the victor.

The twist to every show is that the chefs must use a “secret ingredient” in each of their dishes. The secret ingredient is not known ahead of time by the chefs, so the two chefs have another big stress added into an already stressful day!

It’s a great show, and I always enjoy watching the creative genius of the chefs. The Iron Chef usually wins the battle, but occasionally a challenger chef will win!

In tensile testing, there are 5 “secret ingredients” to make sure the materials testing produces good results for the client. Here are those ingredients:

(1) Specimen Preparation – the specimen needs to be carefully machined, so that the sample is representative of the material being tensile tested. This might mean crafting several specimens from one larger casting of material. The specimen axis should be properly aligned, and the dimensions of the specimen must be within tight tolerances, because much of the data is calculated using the specimen dimensions.

(2) Testing Machine – the hydraulic, universal testing machine being used for tensile testing must be calibrated, and kept in good working order.

(3) Specimen Alignment – the specimen must be properly aligned within the grips. This means that the tensile testing specimen is properly machined with a correct axis, and also the specimen must be properly centered within the grips of the universal testing machine.

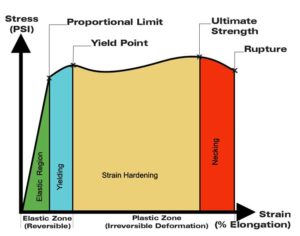

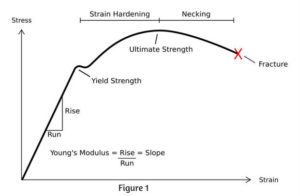

(4) Stress Strain Diagram – a picture is worth a thousand words, and any lab that does tensile testing should provide you with stress strain curves of how your specimens performed.

(5) Detailed Reporting – a thorough report is a must for tensile testing, as a great deal of data and information can be derived from each specimen test on the universal testing machine. Your report should include stress strain curves, discussion of elastic and plastic deformations, your material’s Poisson’s ratio, yield points, full identification of the material that was tested, and a statistical summary of the data.

Check out our other social media pages!