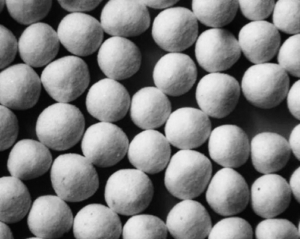

If you thought 100 mesh sand was small, get ready for microproppants!

If you thought 100 mesh sand was small, get ready for microproppants!

In the lab, the testing gets harder as the sand and proppant gets smaller. This is because the small 100 mesh (sand between 70 and 140 meshes) sand gets a static charge when moving it around during testing.

For instance, when loading the crush cylinder, it’s critical to have a level surface of sand.

But with small material, the static charge as the sand is dropped into the cylinder causes it to mound on one side.

We have a way to fight this, but it’s slow and painstaking.

Now, prepare the way for microproppants!

Microproppants seemed to enter the conversation from some patent work and publishing that Halliburton has done.

*** In a fascinating patent (Patent #8,985,213) from 2015 with the title “Micro proppants for far field stimulation”, inventors at Halliburton make the following claims, among others:

(a) they refer to micro proppants as being smaller than 200 mesh

(b) micro proppants can produce “dendritic fractures” that can greatly expand the network of fractures (and then production!)

(c) there are micro proppants that can be generated downhole!

(d) micro proppants can also be manufactured, then pumped downhole

(e) they are careful to say micro proppants can “potentially improve recovery from the formation”

Now, in a 2017 SPE paper with the title “Enhancement of Well Production in the SCOOP Woodford Shale through the Application of Microproppant” Halliburton is claiming to get double digit (ie 15%) production enhancements through the use of microproppants.

Interesting times!

We are continuing our research into micro proppants here at the lab, and will routinely report the findings to you!

In the meantime, for all kinds of proppant testing, including micro proppant testing, visit us here!

Check out our other social media pages!